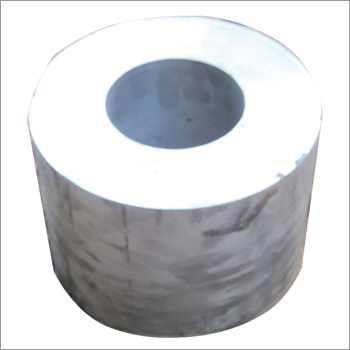

Steel Casting Charging Box

Steel Casting Charging Box Specification

- Surface Treatment

- Shot Blasted

- Process

- Sand Casting

- Product Type

- Charging Box for Steel Casting

- Material

- High-grade Steel

- Surface

- Smooth

- Dimension (L*W*H)

- 1800 x 1000 x 900 mm

- Size

- Standard / Customizable

- Weight

- Approximately 1.8 - 2.2 Tons

- Application

- Steel Plant, Foundry, Furnace Charging

- Color

- Grey

Steel Casting Charging Box Trade Information

- Minimum Order Quantity

- 2 Tons

- Supply Ability

- 10000 Tons Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As Per Buyers Requirement & Order

- Main Domestic Market

- All India

About Steel Casting Charging Box

The Charging Box we deal in is needed to improve the customer's overall experience. The box allows for effortless use in several applications. This is a simple to use box that boasts of advanced functionality in assorted applications. The box is useful for the retail associates and has been accessible with advanced technology and high utility. This is mobile and can be used in many types of industrial surrounds. Offered is a highly mobile solution, applicable in many sectors.Durable Construction for Demanding Environments

Made from high-grade steel and engineered for reliability, the Steel Casting Charging Box stands up to the rigorous demands of industrial use. Its high hardness, tensile strength, and robust welding ensure long-term, safe operation in steel production and furnace charging environments.

Precision Manufacturing and Superior Finish

Manufactured via sand casting and finished with shot blasting, the box offers a smooth, industrial-grade surface. This premium treatment not only reduces material wear but also extends its lifespan and improves resistance to corrosion and elevated temperatures.

Versatile Application with Customization Options

Suitable for steel plants, foundries, and related facilities, the charging box comes in standard dimensions but can be tailored to specific requirements. Its load capacity and high resistance properties make it adaptable for various charging needs within heavy industrial sectors.

FAQs of Steel Casting Charging Box:

Q: How is the Steel Casting Charging Box manufactured for maximum durability?

A: The charging box is produced using a sand casting process with full seam welding. This manufacturing method, coupled with shot-blasted surface treatment, ensures enhanced structural integrity and resistance to both mechanical stress and environmental corrosion.Q: What makes this charging box suitable for high-temperature and corrosive operations?

A: The box is constructed from high-grade steel with industrial-grade finishing and a smooth surface. It features high heat and corrosion resistance, making it reliable for furnace charging and other demanding operations that involve elevated temperatures and exposure to harsh substances.Q: When is it ideal to use the Steel Casting Charging Box in an industrial setting?

A: This box is suited for continuous use in steel plants, foundries, and any application requiring safe and efficient transport or loading of heavy materials. Its design supports up to 2.5 tons and can withstand the wear and tear of frequent furnace charging.Q: Where can I source this Steel Casting Charging Box?

A: The charging box is supplied, exported, and manufactured by companies in India specializing in industrial steel components. It is available for purchase both as a standard option and with customizations for specific site requirements.Q: What are the process and benefits of the boxs surface treatment?

A: The surface is shot blasted, resulting in a smooth, industrial-grade finish. This process enhances the boxs resistance to corrosion, prepares it for high-stress operations, and prolongs its service life beyond eight years of continuous industrial use.Q: Can the Steel Casting Charging Box be customized for unique facility requirements?

A: Yes, besides the standard dimension of 1800 x 1000 x 900 mm, manufacturers offer customization to suit different plant layouts or operational needs. Custom sizes and specifications can be discussed with the supplier to match specific charging tasks.Q: What are the main usage benefits for steel plants and foundries?

A: The boxs robust build, high load capacity, and resistance to thermal and corrosive wear make it highly beneficial for safe, efficient furnace charging and material handling, reducing downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Castings Category

Steel Casting Bearing Housing

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Bearing Housing

Size : Custom sizes available

Material : Other, Highgrade cast steel

Color : Metallic grey

Idler Casting

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Idler

Size : Standard and customized sizes available

Material : Other, Cast Iron or Cast Steel

Color : Natural grey or painted (grey, black, as required)

Steel Casting Hub Assembly

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Hub Assembly

Size : Customizable

Material : Steel

Color : Grey/Metallic

Cast Iron Wedge

Price Range 85.00 - 500.00 INR / Kilograms

Minimum Order Quantity : 2 Tons

Product Type : Other, Wedge

Size : Standard/Custom

Material : Other, Cast Iron

Color : Grey / Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry